Water Purification Service Programs

|

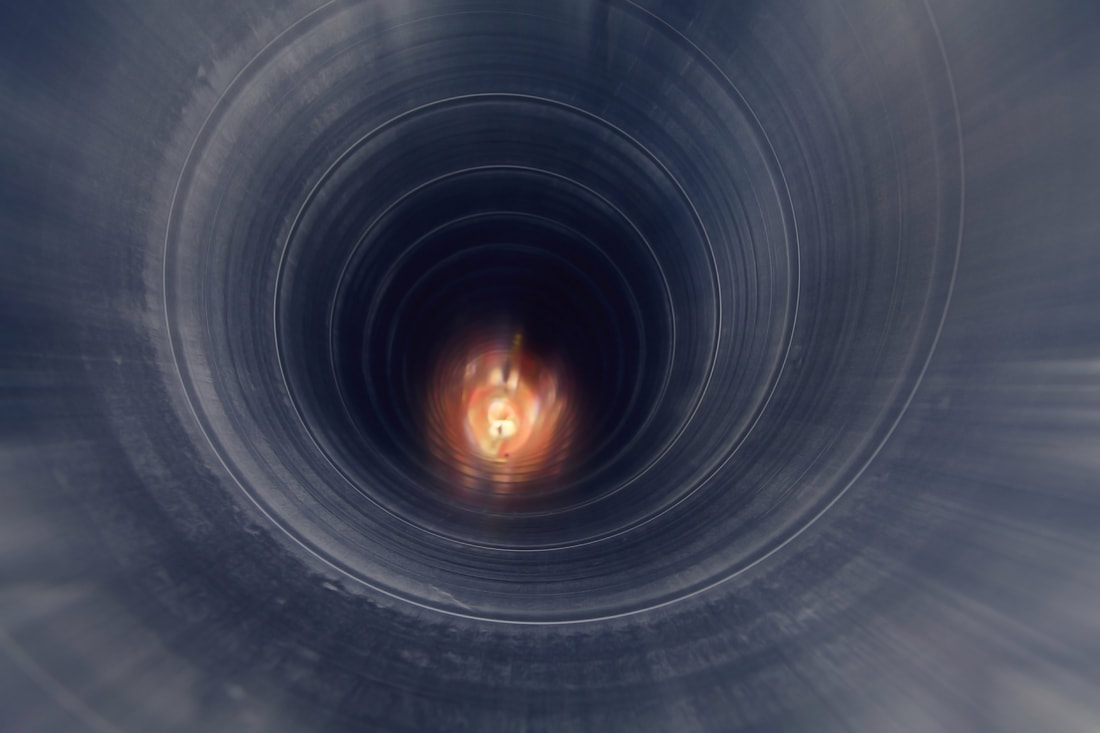

Hydrovida is one of the top commercial water treatment companies that performs maintenance and services on commercial and industrial water purification equipment including sand filtration, carbon filtration, ultrafiltration (UF), reverse osmosis (RO), Electrodeionization (EDI) and softeners systems. In addition to the service aspect, Hydrovida also provides custom tailored, environmentally friendly chemistry to optimize virtually any water purification system. Unlike other commercial water treatment companies, our goal is to keep water processing systems running as smooth as possible with the goal of minimized operational, energy and membrane replacement costs, while also maintaining the highest efficiency attainable, helping save on water usage by maximizing recovery. Along side with Hydrovida's eco-friendly RO chemistry line, our water purification system healthcare programs are designed to optimize any water water processing system, increasing production and extending the life of costly purification filter elements.

|

Cooling Tower Treatment Programs

|

Hydrovida's prime initiative is to produce sustainable practice wherever possible. In cooling tower applications this includes a strong program that minimizes energy consumption, saves water and uses formulated, biodegradable and environmentally-friendly chemistry. Many chemistries used in traditional cooling tower treatment programs may be he goal is to make cooling towers a positive application for both humans and the environment. Hydrovida is devoted to developing the ideal sustainable treatment of cooling towers and hopes to create a world where water pollution is completely halted. Contact Hydrovida to be connected with your local representative to get a free program and equipment assessment or to learn more about Hydrovida's cooling tower and HVAC treatment programs and specialized chemistry.

|

Boiler Treatment

|

Hydrovida provides water treatment programs, services and eco-friendly chemistry for steam boilers and hot water heating boilers. Without proper treatment, boilers will either produce hard scale, or will experience aggressive corrosion. Scale formation dramatically decreases the efficiency of the boiler by decreasing the thermal conductivity of the heat transfer surfaces, which in turn exponentially drives up energy and operating costs. Corrosion to boilers can lead to hundreds of thousands in premature replacement costs. Hydrovida has a line of biodegradable boiler chemistries that effectively prevent scale formation and keep heat transfer surfaces clean allowing for an efficient energy saving boiler system. Contact Hydrovida for a no cost boiler treatment assessment.

|

Closed Loop Treatment

|

Closed loop systems are the most common type system used in HVAC for commercial and industrial applications. The purpose of HVAC closed loop systems is to transfer heat through a circulating water source. This is used for heating, air conditioning and in many process operations. Although effective in their purpose closed loops are a potential breeding ground for anaerobic bacteria. These bacteria if left unchecked can cause devastating microbial influenced corrosion. In addition, if the closed loops are not passivated and treated properly, metal in the loops will eventually corrode and fail. Traditional closed loop treatments rely on nitrites to act as oxygen scavengers in closed loops. Hydrovida has adopted newer chemistries that effectively treat, clean and passivate closed loops, while also being eco-friendly and more biodegradable. Hydrovida provides service programs for closed loop systems to keep expensive infrastructure intact, while also taking in consideration of bleed and eventual discharge from chemicals put in the loop.

|