Cooling Tower Water Treatment

Hydrovida provides eco-friendly chemistry and cooling water equipment and cooling tower water treatment services. Unlike other cooling tower water treatment companies, our service programs are custom-tailored to our clients needs and are completely based around the available feed water makeup to the cooling towers. Hydrovida is big on water conservation and treats cooling water with makeup water sources such as RO concentrate, recycled wastewater and even pond water. Our programs can be tailored to have remote monitoring to have trending and desired water parameters available at a click of a mouse.

|

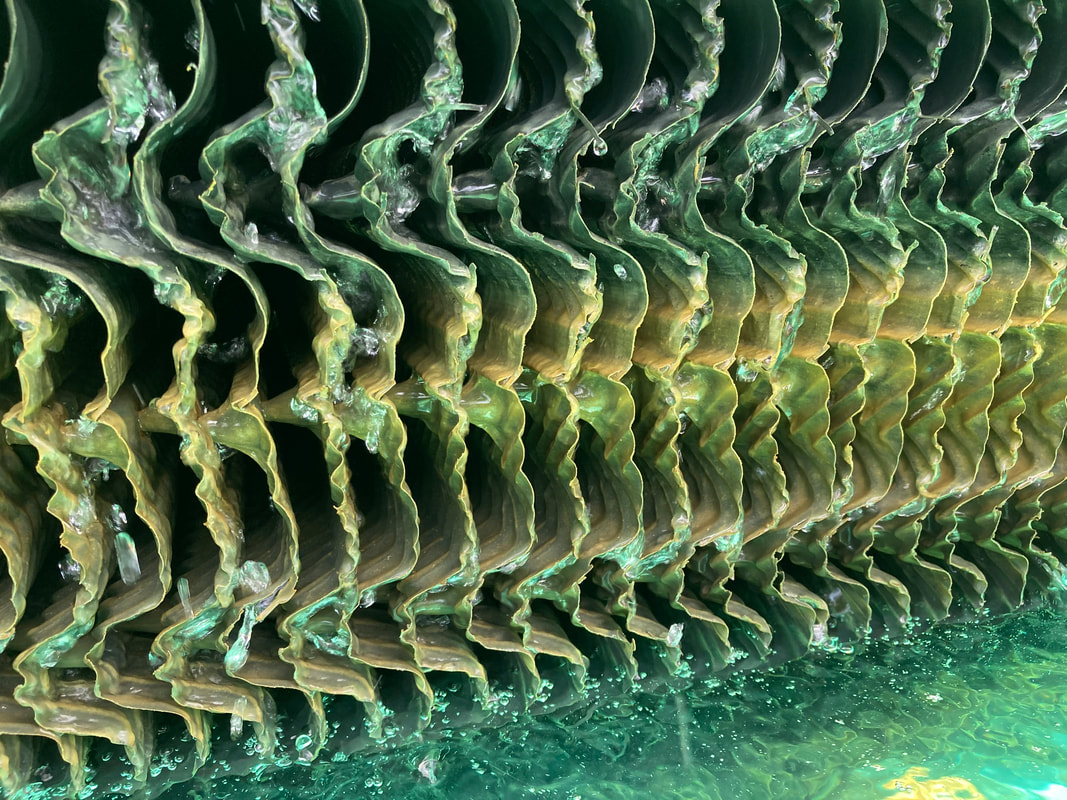

Cooling Tower CleaningKeeping a cooling tower clean is imperative to maintaining a successful water treatment program. Excess dirt and debris can lead to increased chemical consumption and can lessen the effects of the water treatment chemicals ability to prevent scale and corrosion. Hydrovida performs extensive cooling tower water treatment services that combine formulated chemistry and mechanical cleaning means to remove excess scale, dirt and debris from the tower fill, sumps and distribution basins. A clean cooling tower will help keep chiller bundles free of debris and scale, leading to increased efficiency and a much smaller carbon footprint.

|

Importance of Water Treatment

|

|

A great water treatment program containing effective customized chemistry is essential in maintaining costly cooling equipment. A poorly managed tower can experience intense scaling and severe corrosion (left image), costing hundreds of thousands of dollars in damage. Additionally, poor treatment can lead to growth and buildup of harmful, contagious bacteria that could sicken people that come near the towers. Cooling towers are the perfect breeding grounds for microbes due to the abundance of nutrients and warm water. It is essential to have trained, experienced personnel evaluate the water conditions and choose a specific treatment plan that will be as effective as possible in protecting both people and the equipment. Lastly, poor treatment that causes bacterial growth or scaling will significantly reduce heat transfer efficiency, leading to exponential increases in energy use and carbon footprints. It is Hydrovida's primary goal to minimize energy use and create a carbon negative footprint. Hydrovida programs can even produce net negative carbon footprints by sequestering CO2 from the atmosphere. Contact Hydrovida today to learn more about our customized cooling water treatment programs.

|

Mobile Cooling Tower TreatmentHydrovida provides cooling tower water treatment system programs for mobile cooling towers for cold storage facilities. Treating cooling towers with the proper chemistry to inhibit scale formation and corrosion are essential to longevity of equipment and minimizing energy needs for operation. We serve many cold storage facilities for agricultural and logistical needs throughout Northern and Southern California. Our mobile cooling tower treatment programs are designed to minimize water usage and maximize heat transfer efficiency throughout the system. We start with a full water analysis of the makeup water to determine a tailored chemical treatment to prevent scaling most likely to occur as dissolved ions concentrate to supersaturated levels. Our scale inhibitors are designed to keep highly insoluble salts dissolved as long as possible, keeping the surfaces on equipment clean.

|